The Servicesound Gallery

Below are images and a brief description of interesting items that have come through Servicesound's door.

Click on the image to enlarge it.

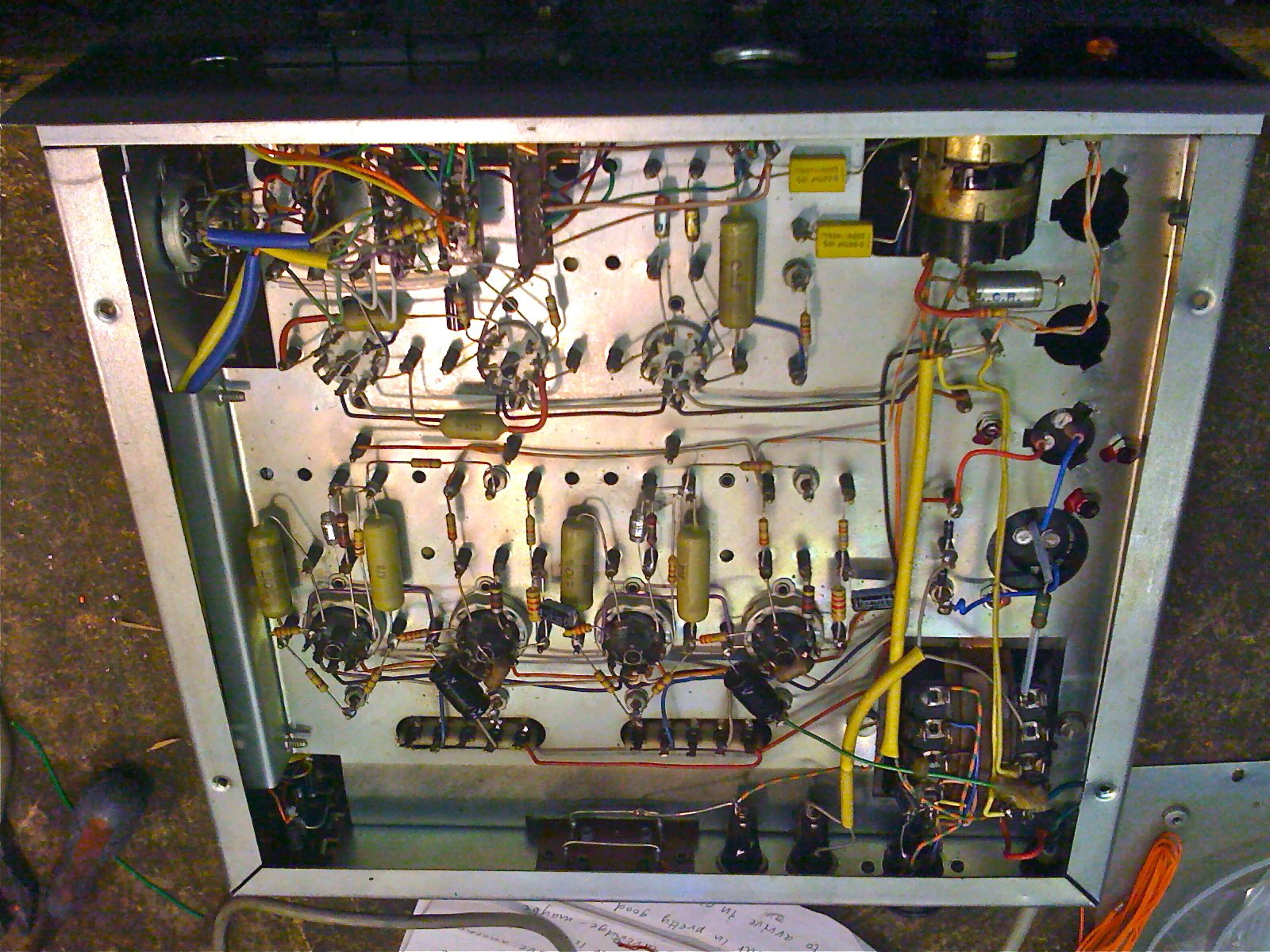

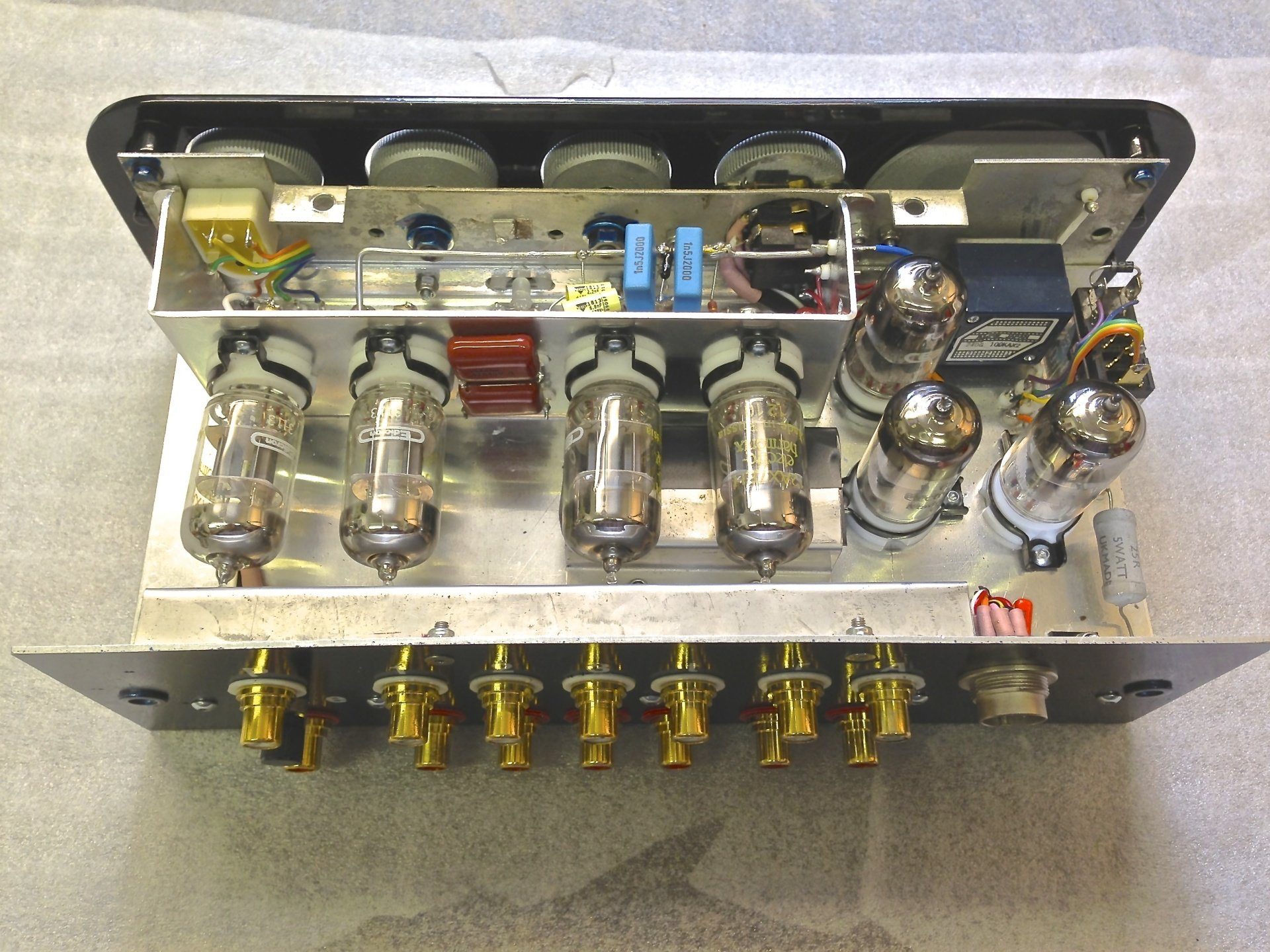

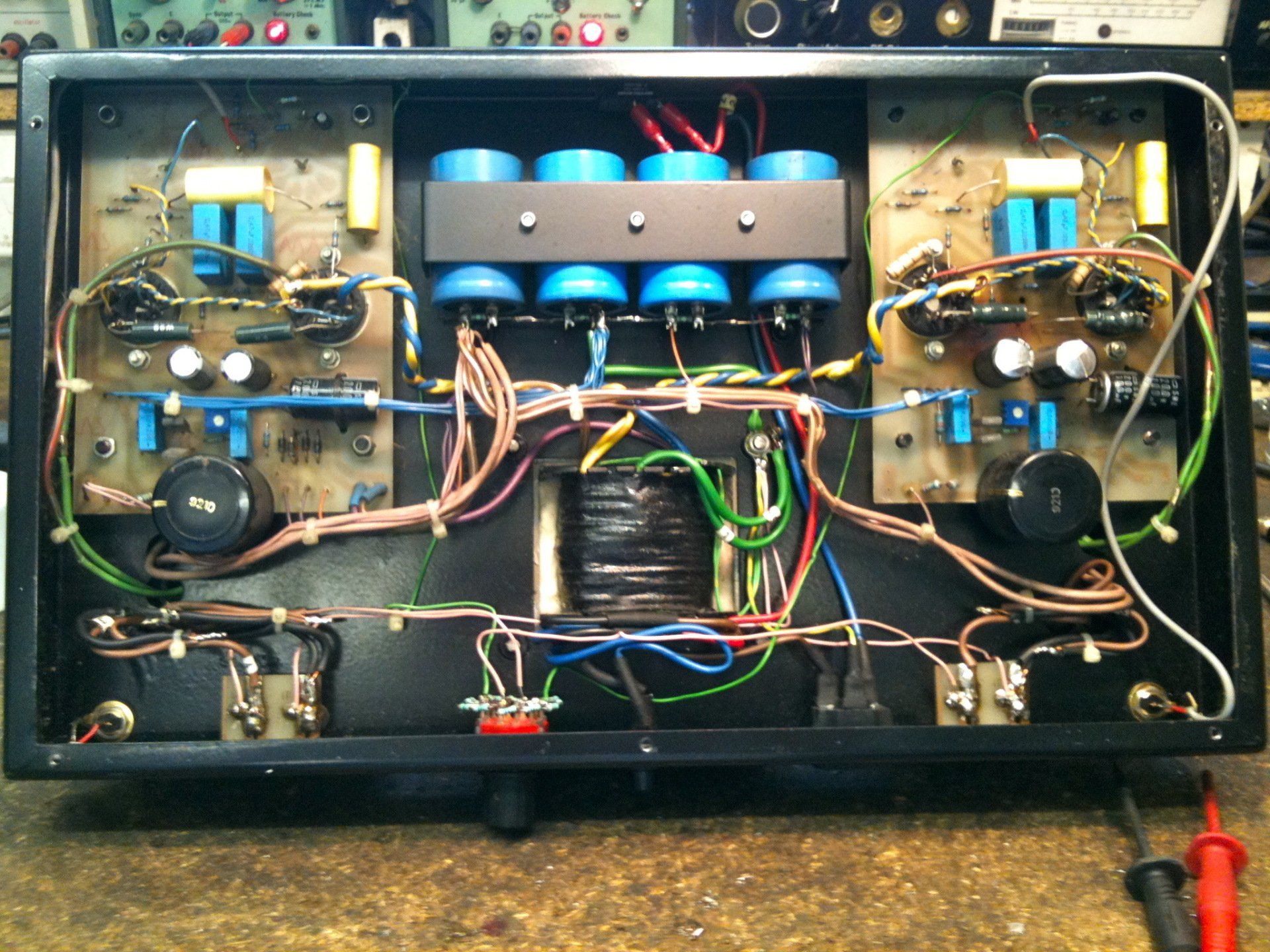

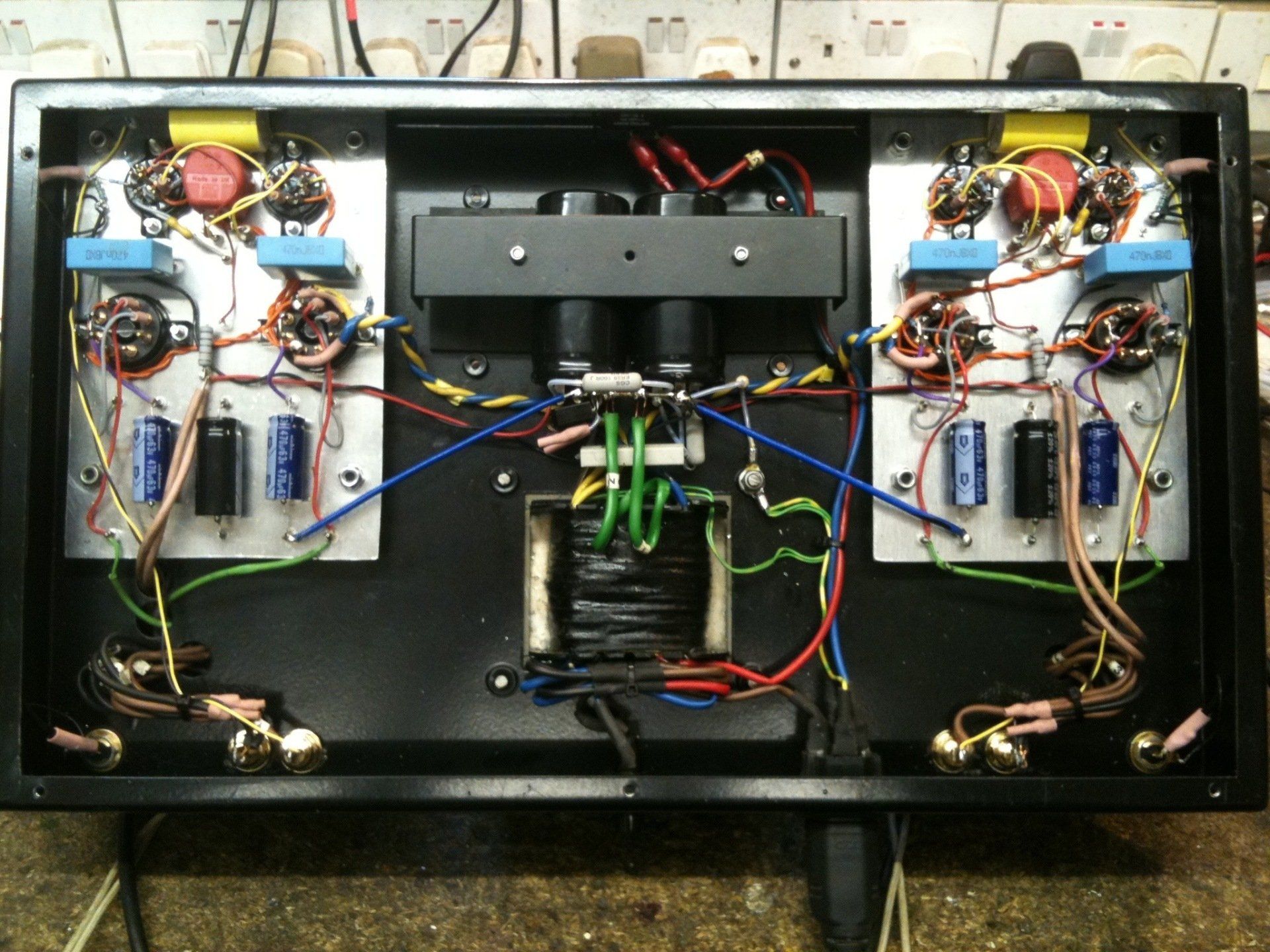

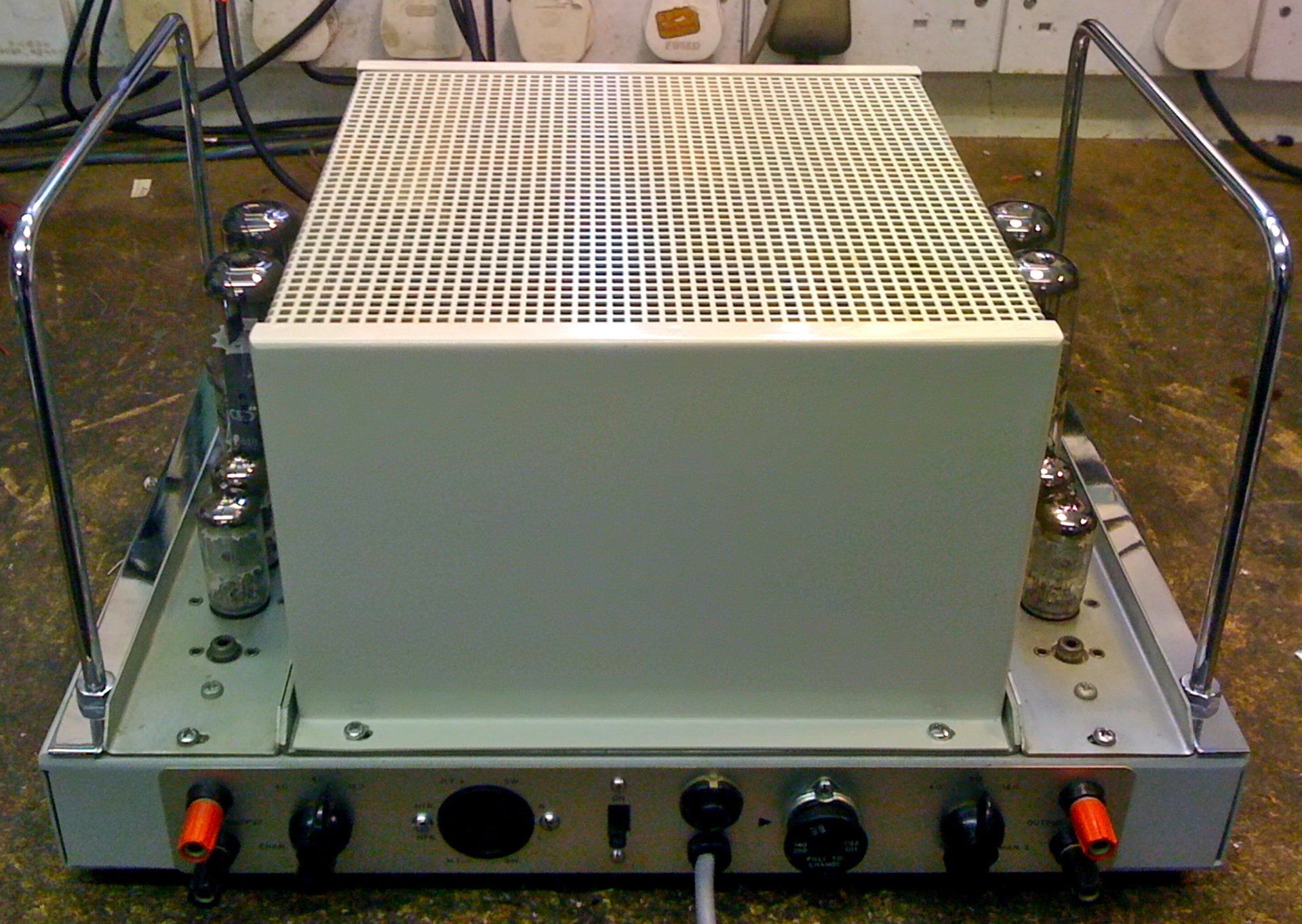

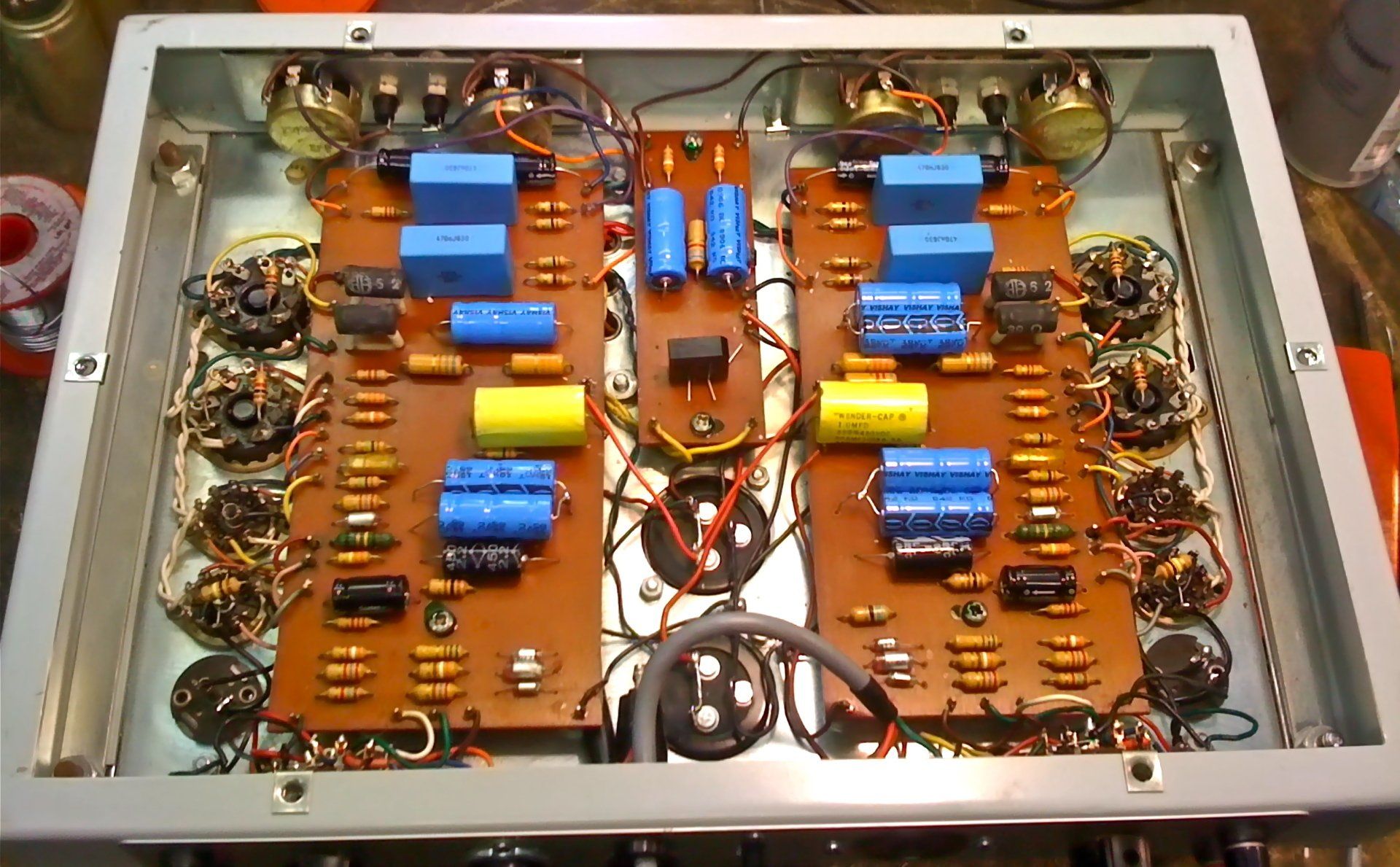

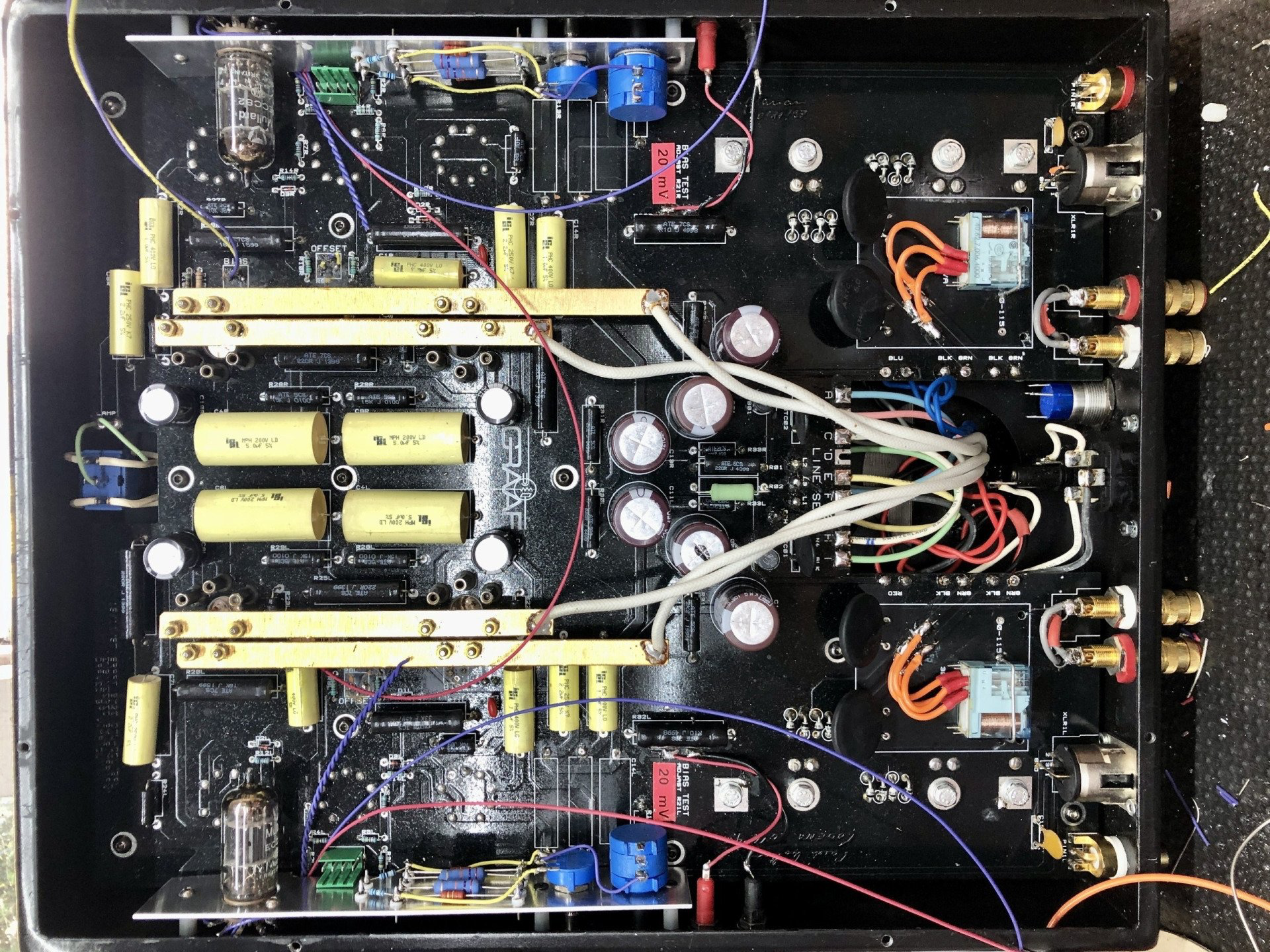

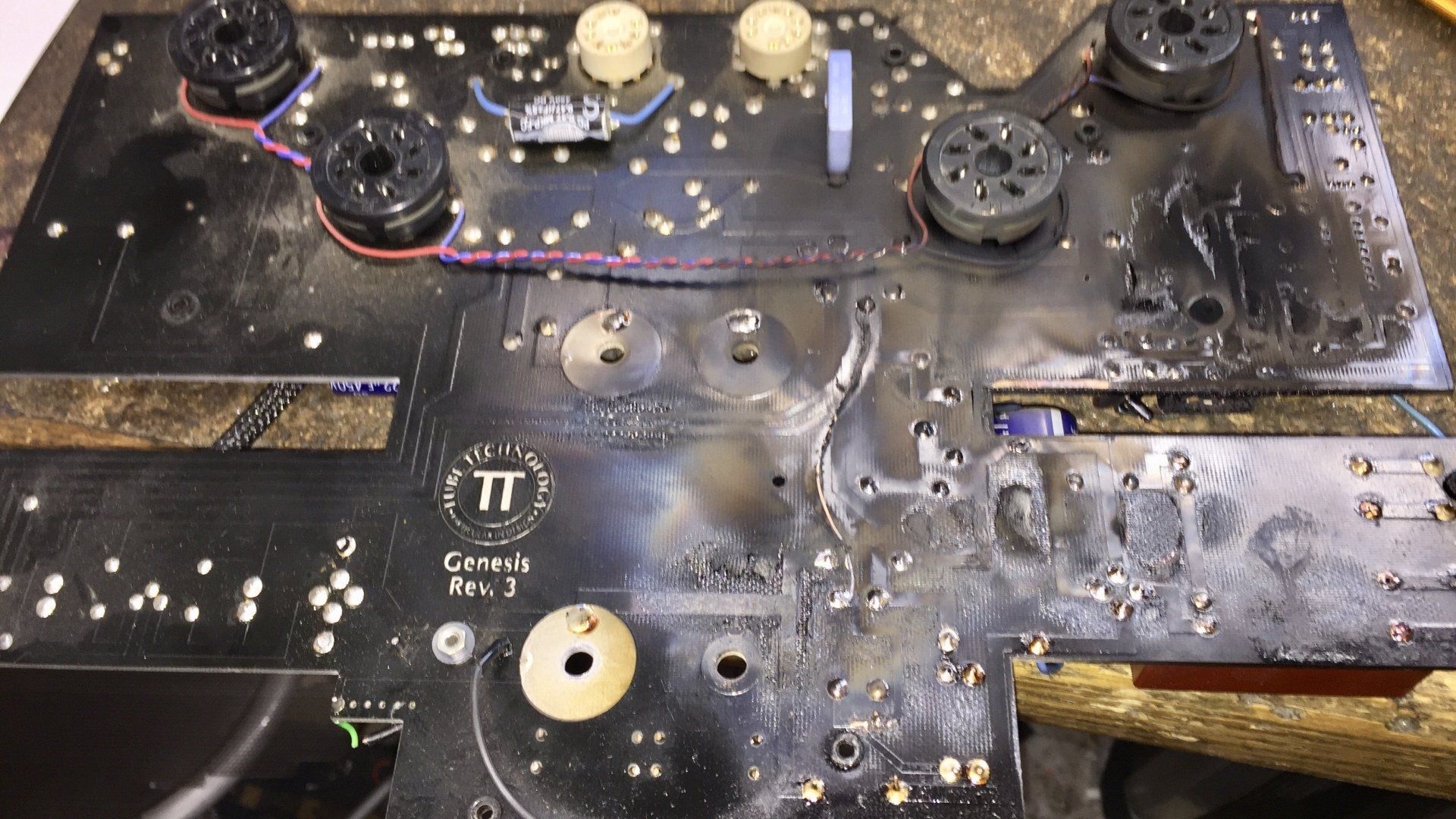

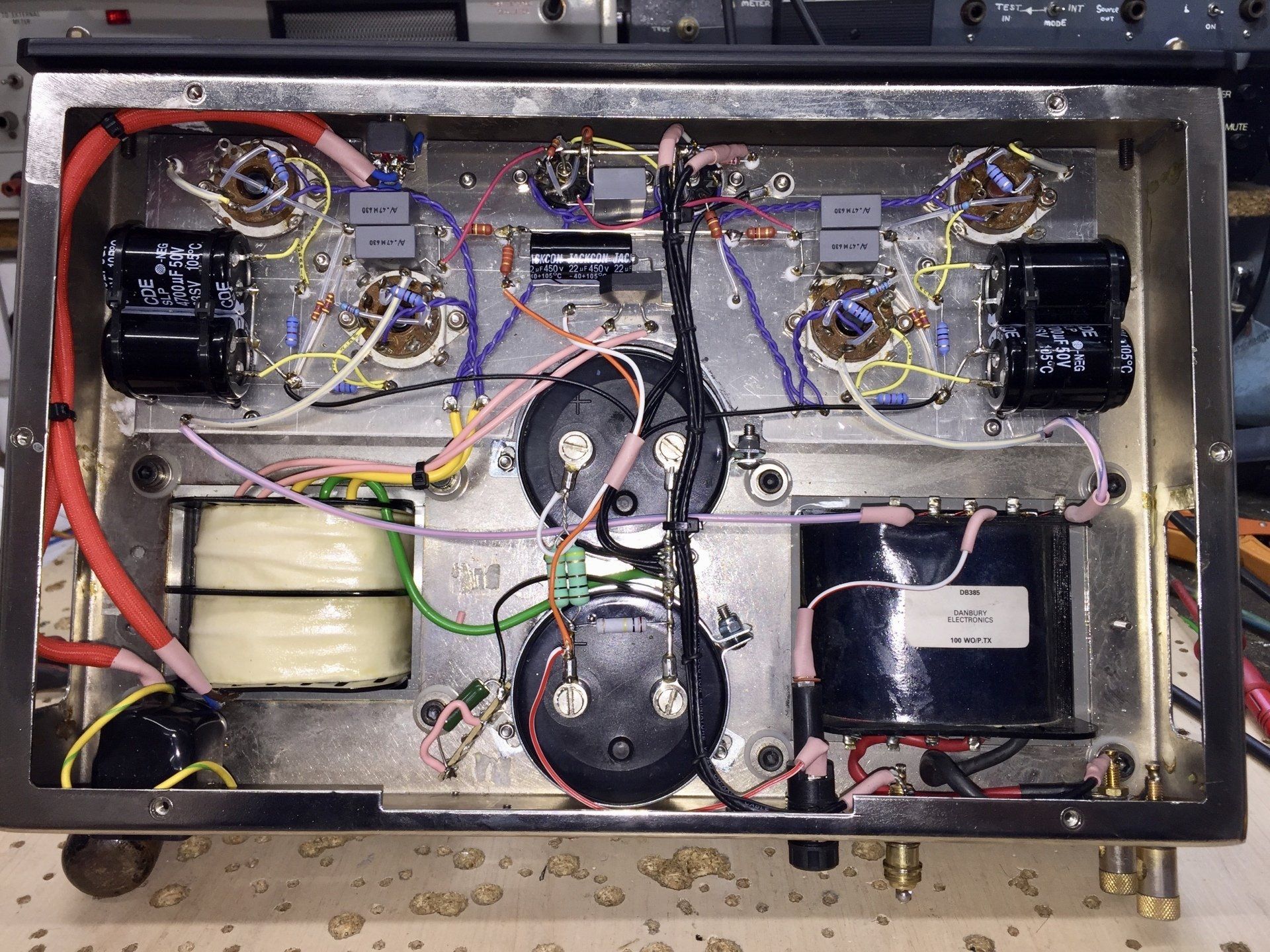

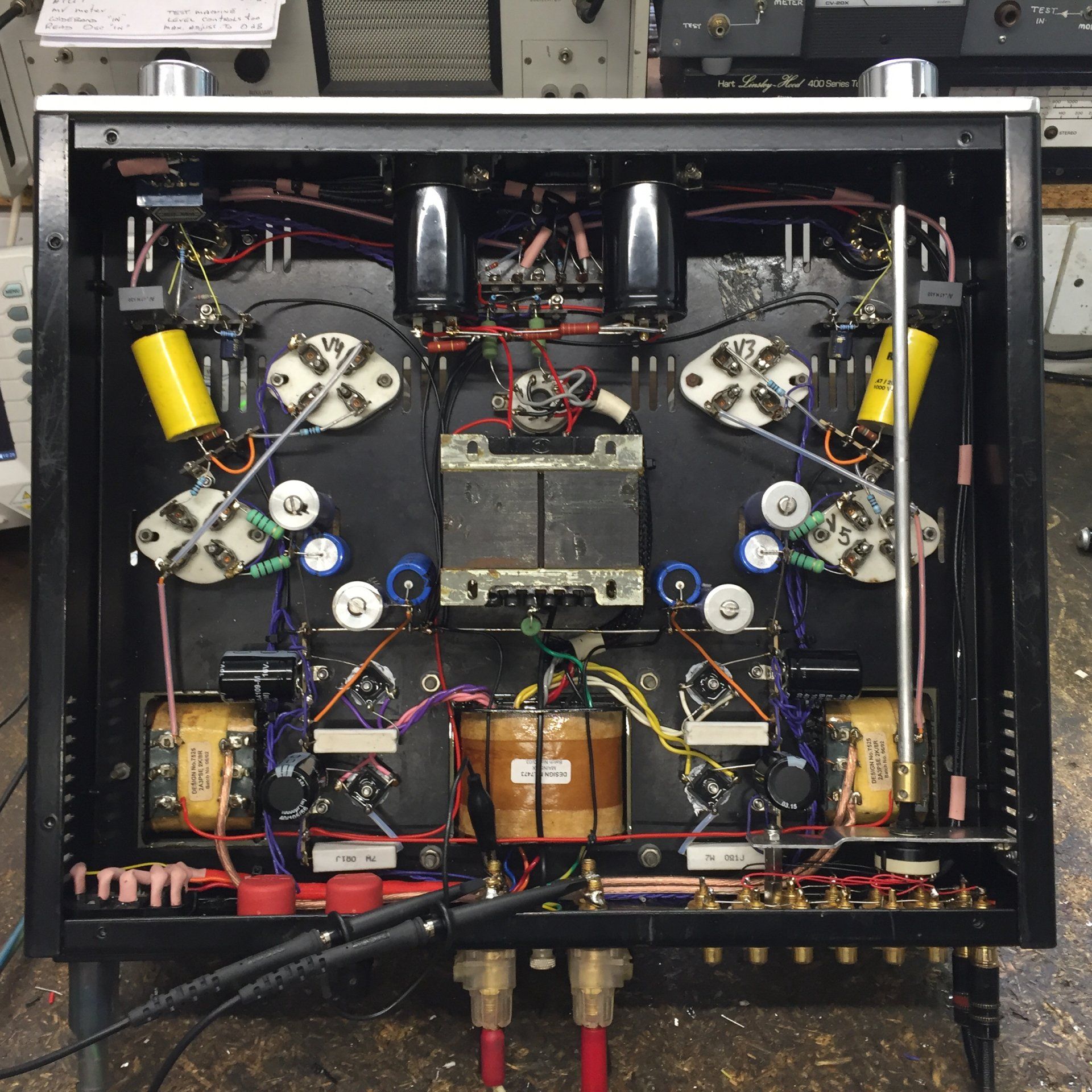

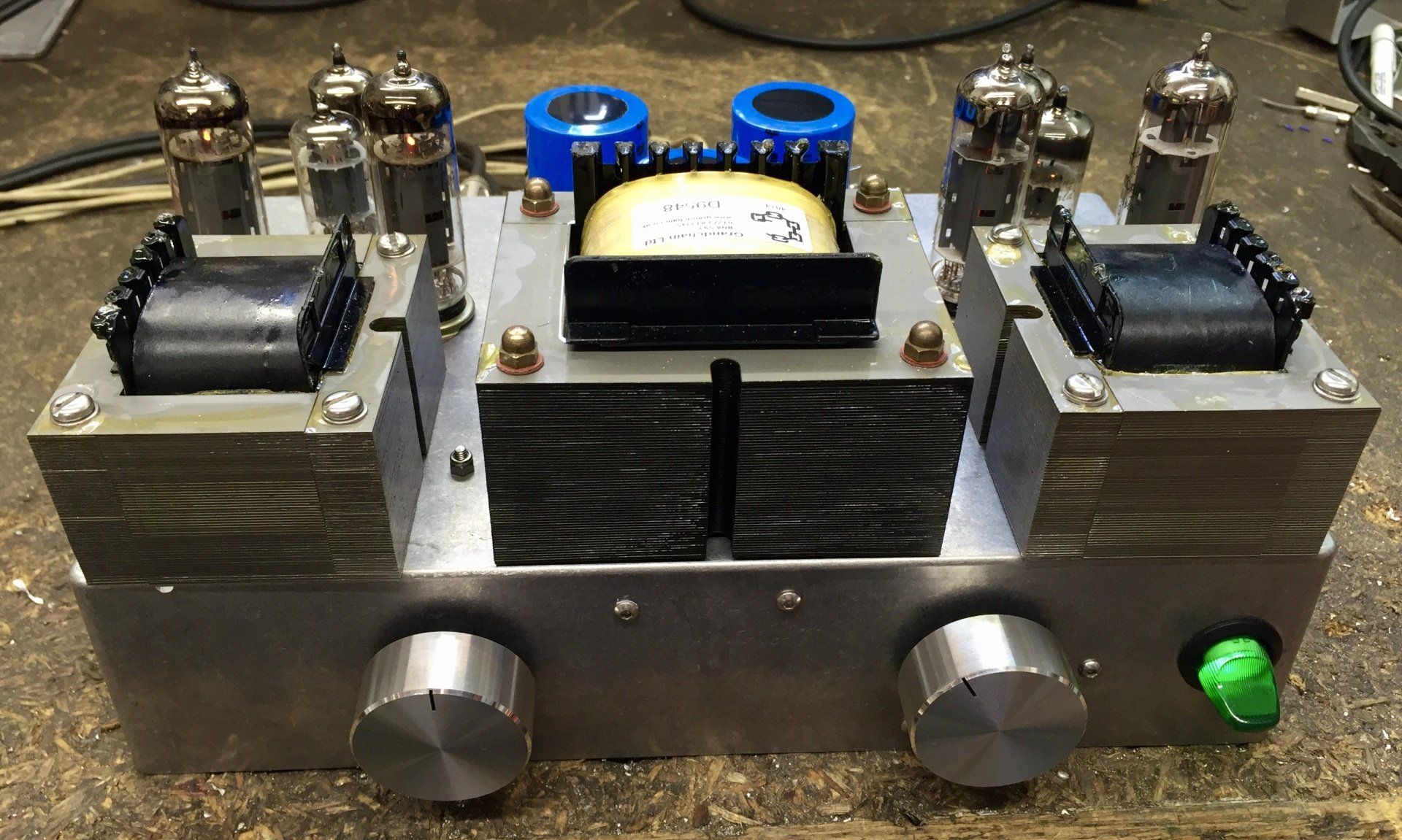

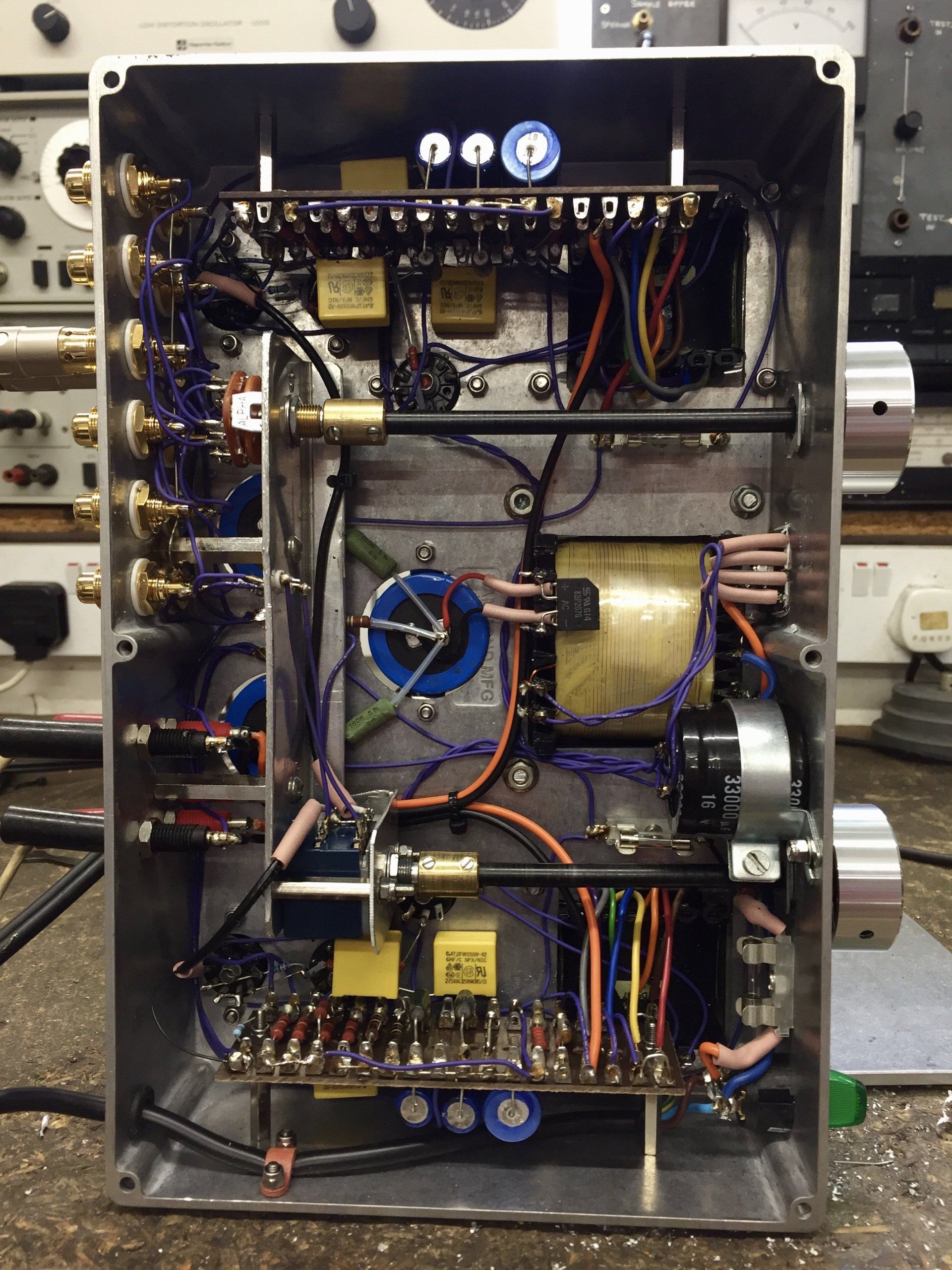

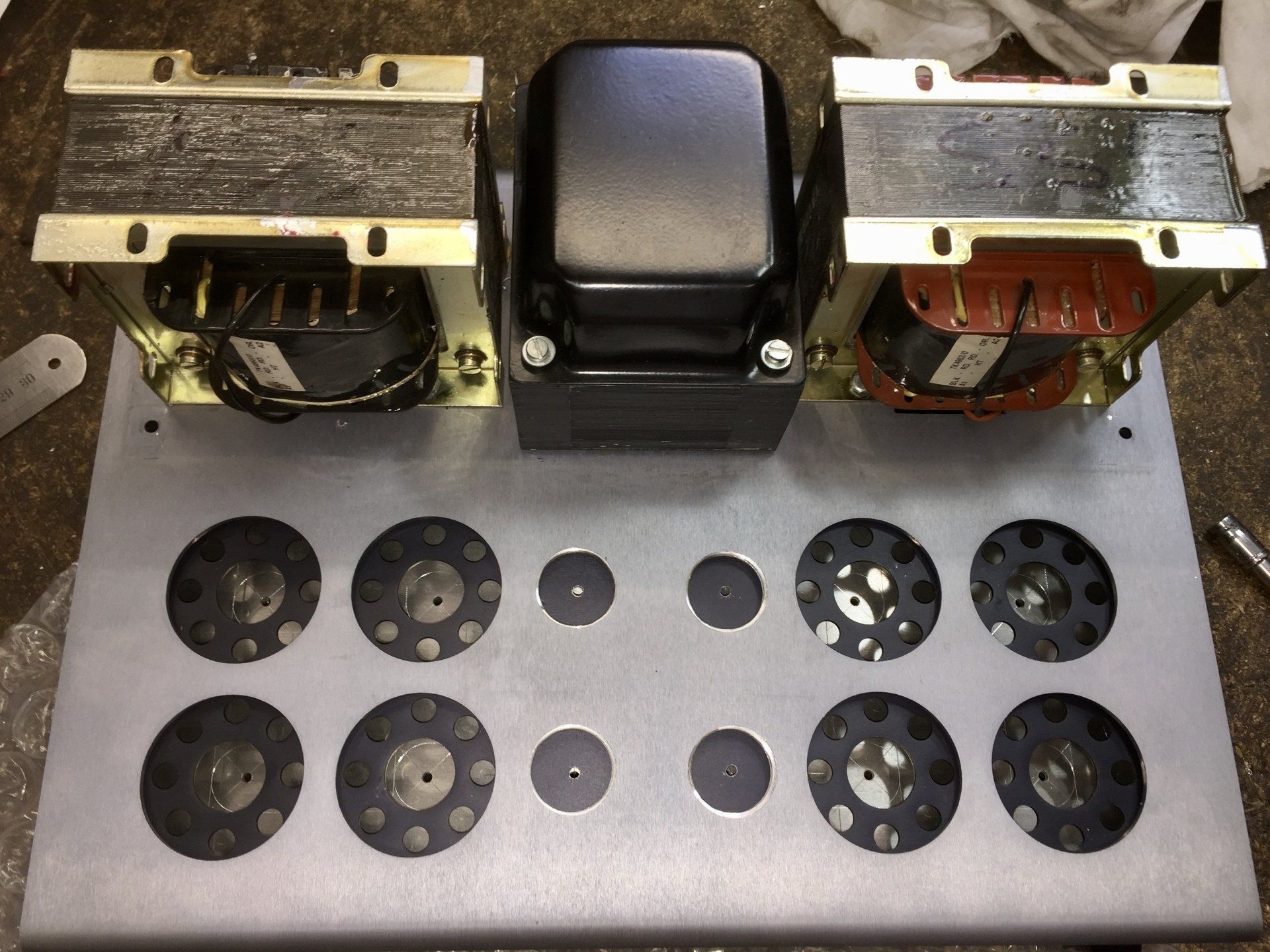

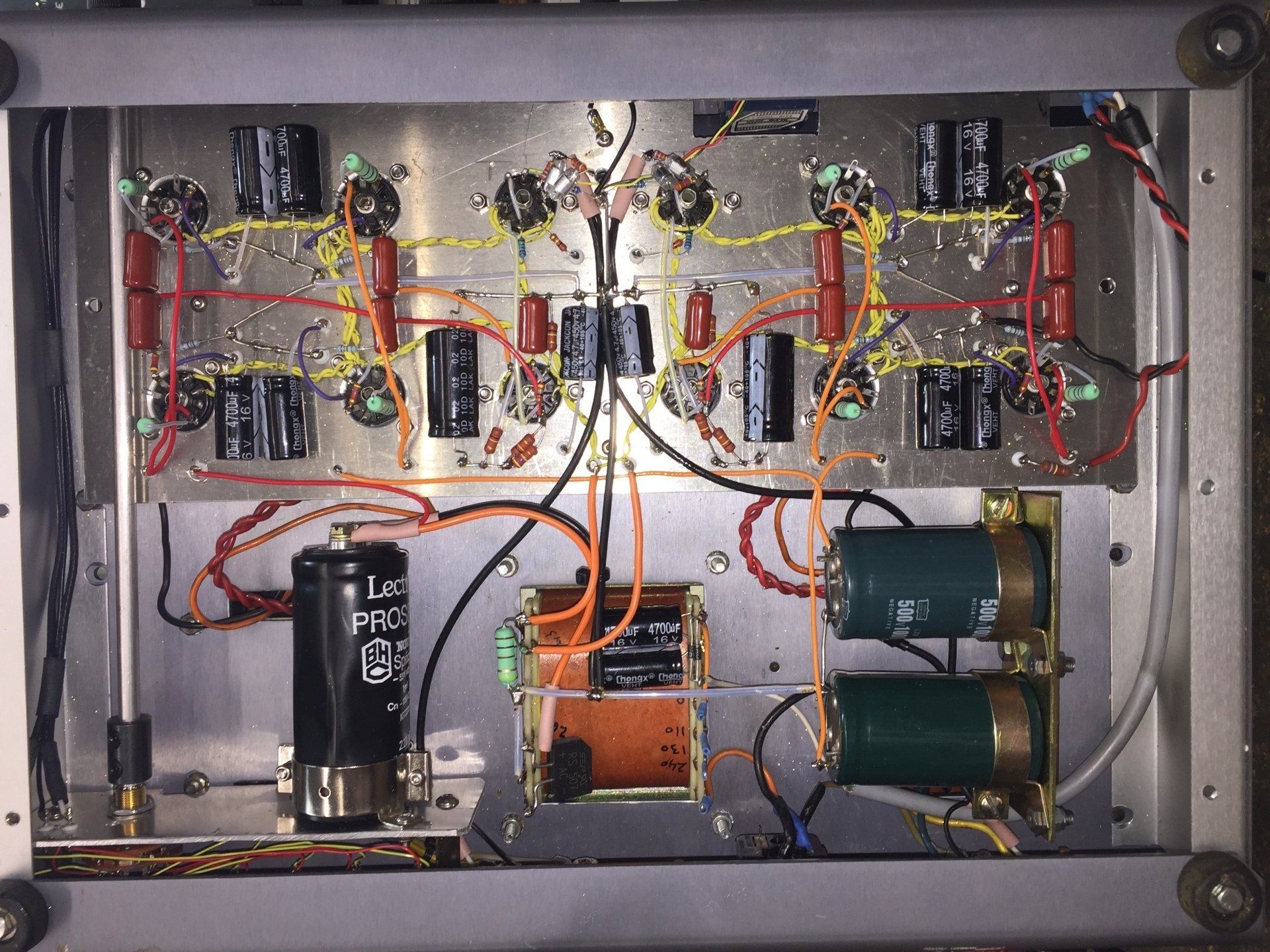

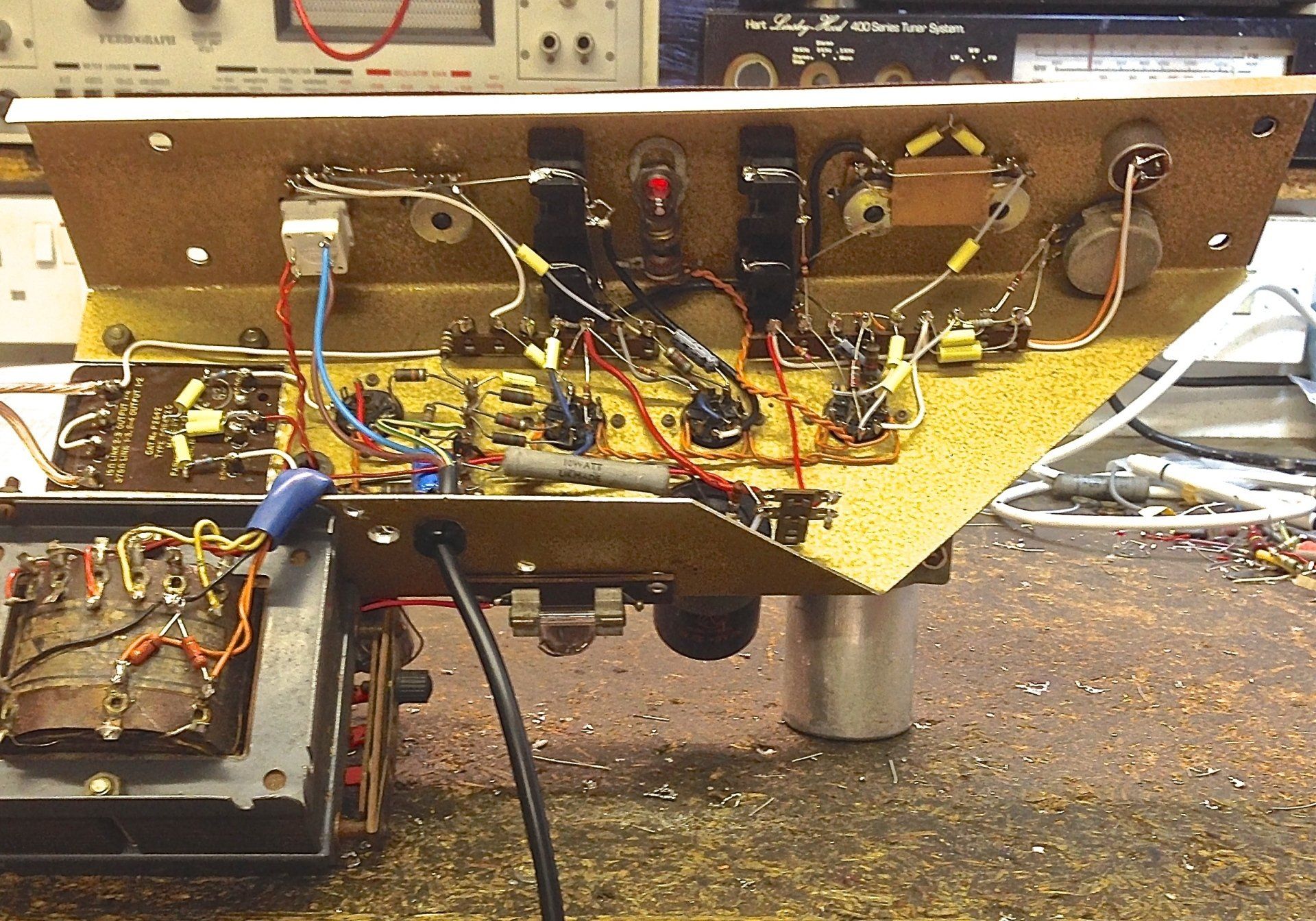

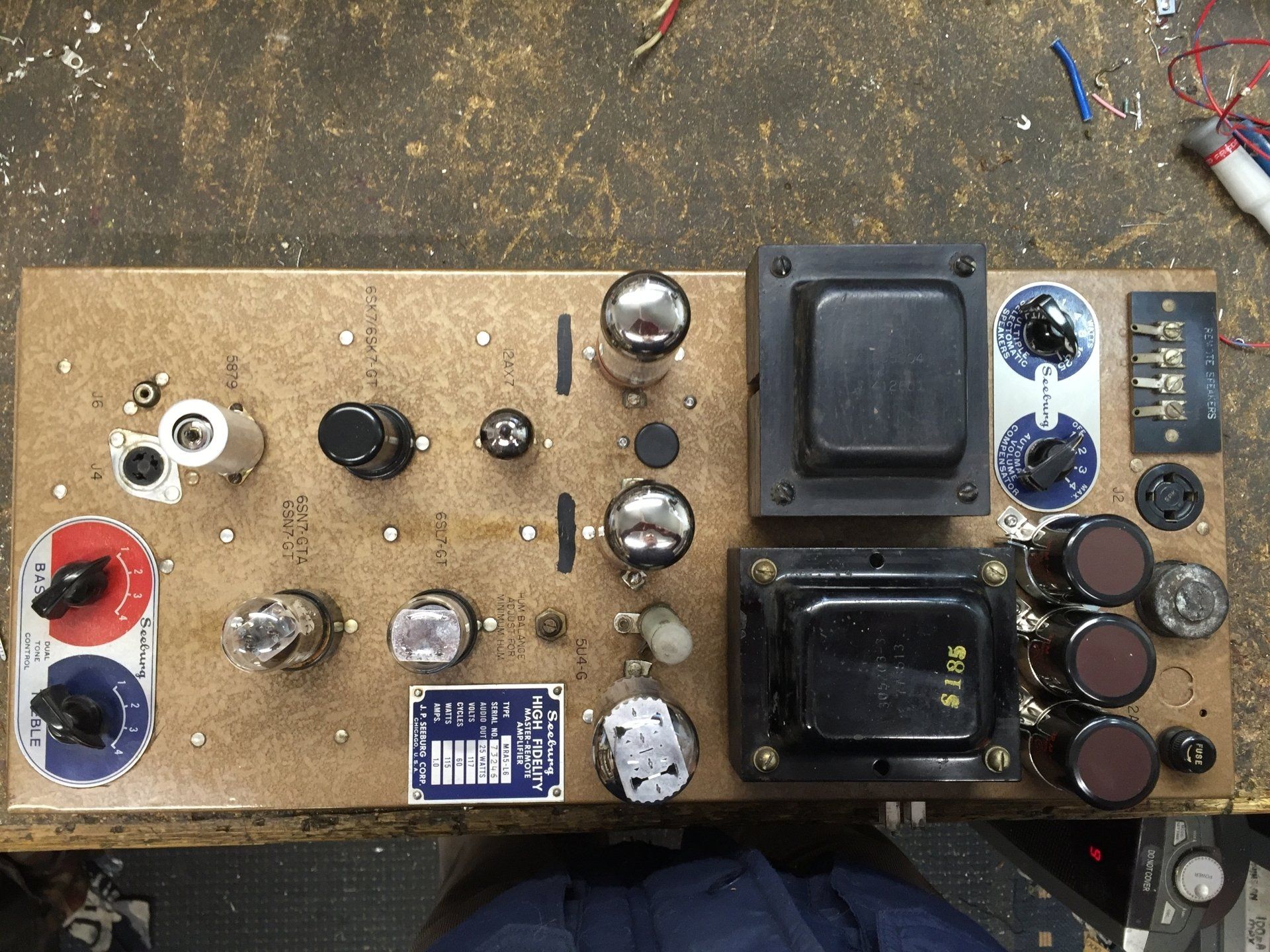

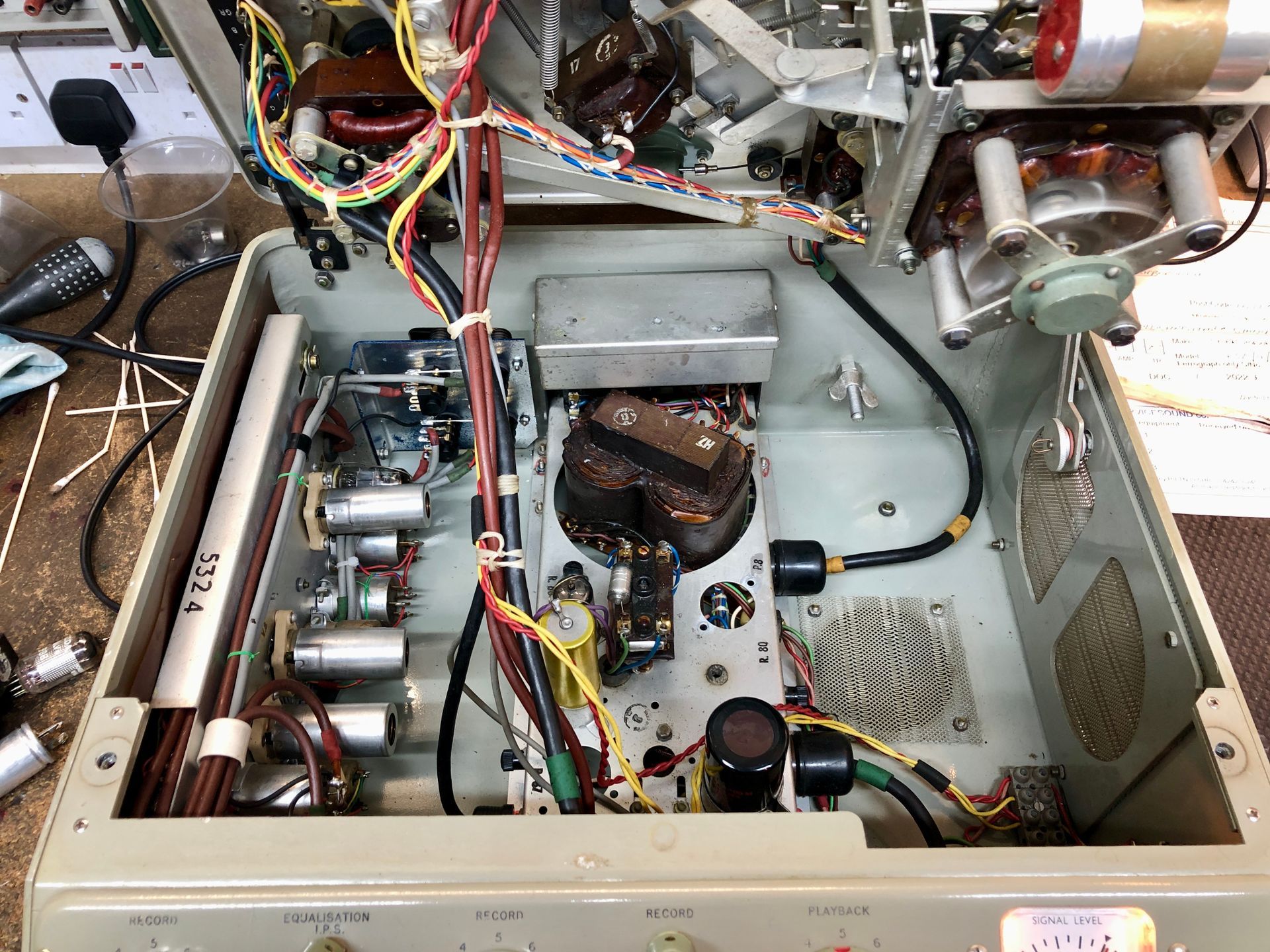

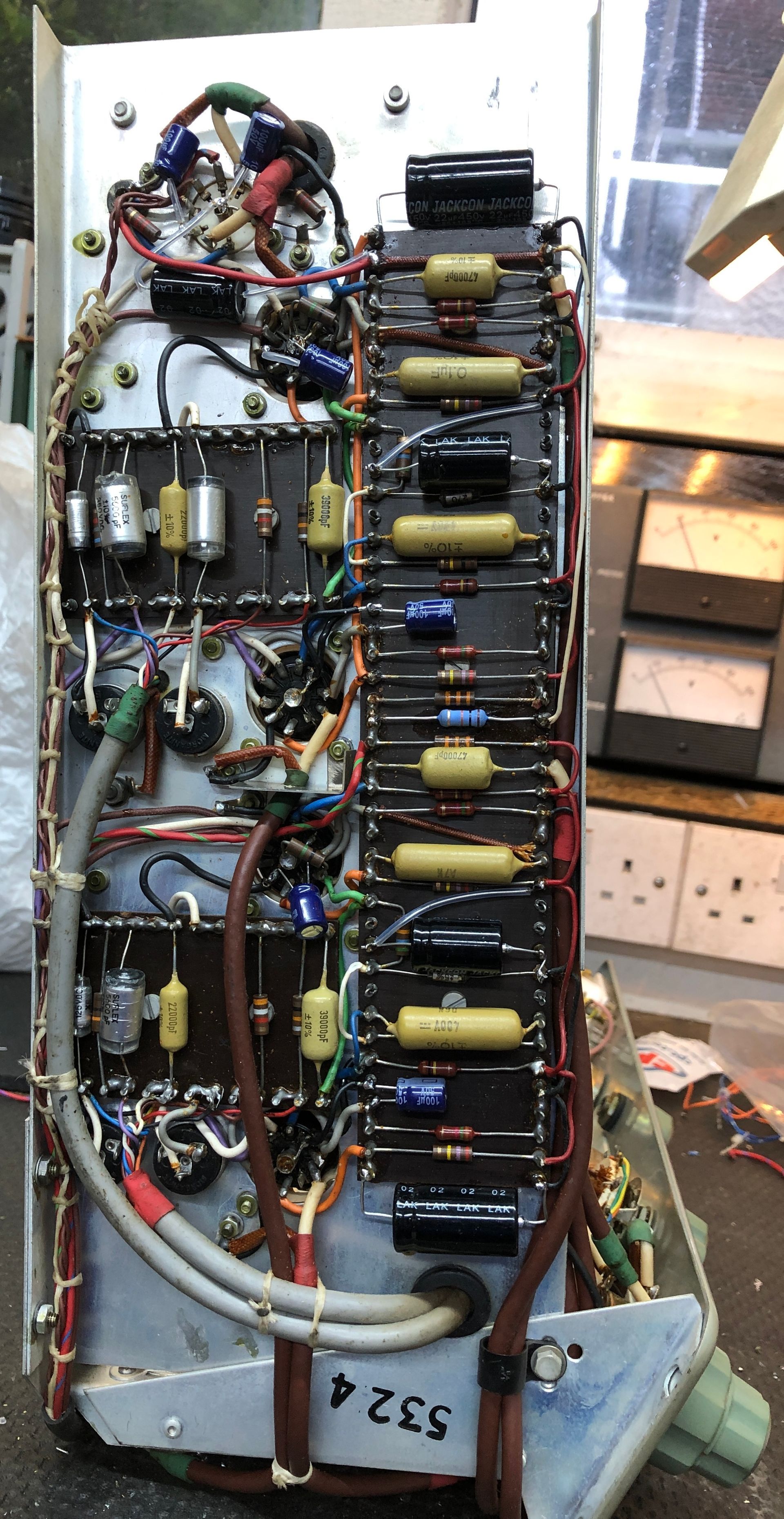

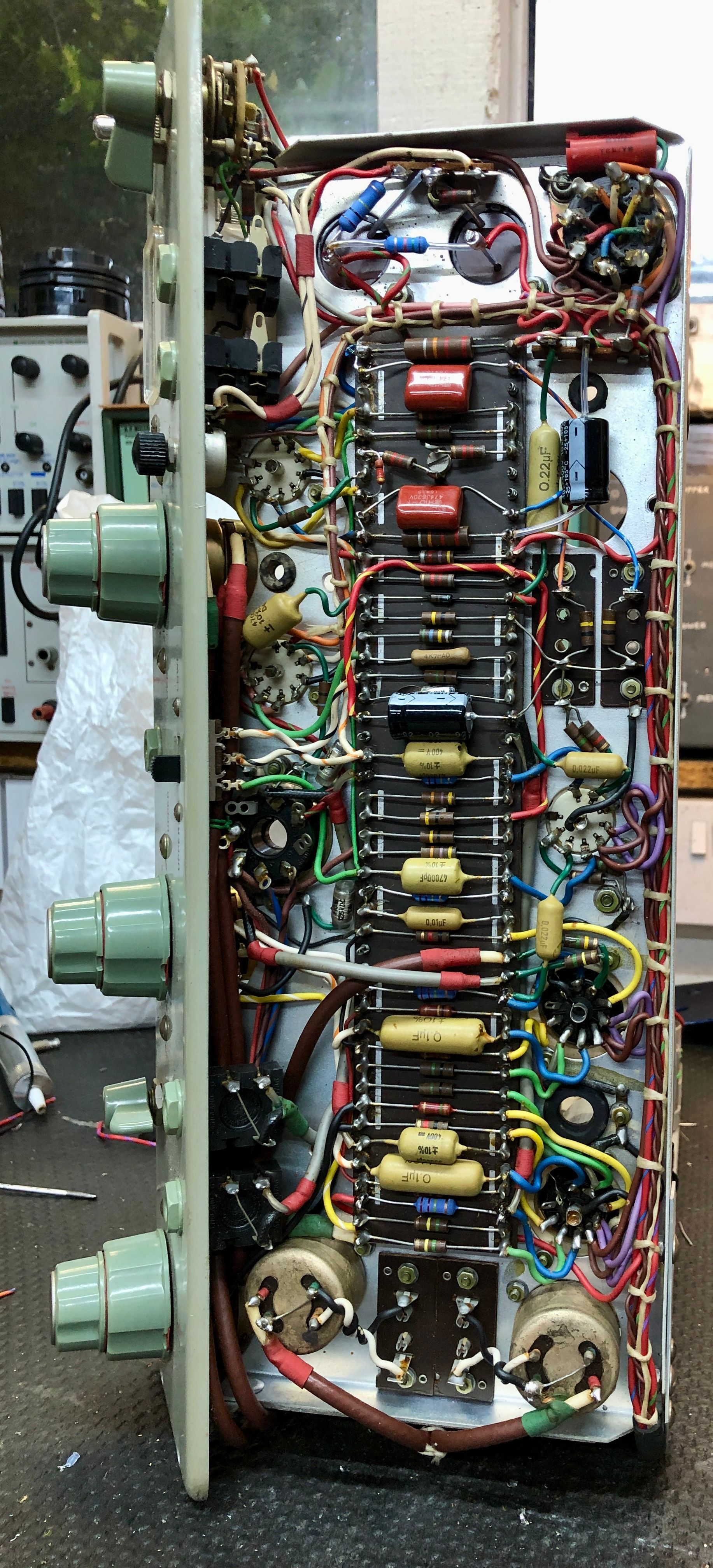

This little French made LECTRON amplifier came in with one channel distorted. This was is a hybrid solid state amplifier using transistors to drive valve output stages. The manufacturer had taken off all the lettering on the transistors plus there is no circuit or design details available anywhere. This hybrid design is not unknown but it is rarely successful. In this instance it was decided to completely redesign the whole amplifier and make it totally valve driven. The finished amplifier greatly exceeds the original in both specifications and sound. It uses British made Partridge transformers.

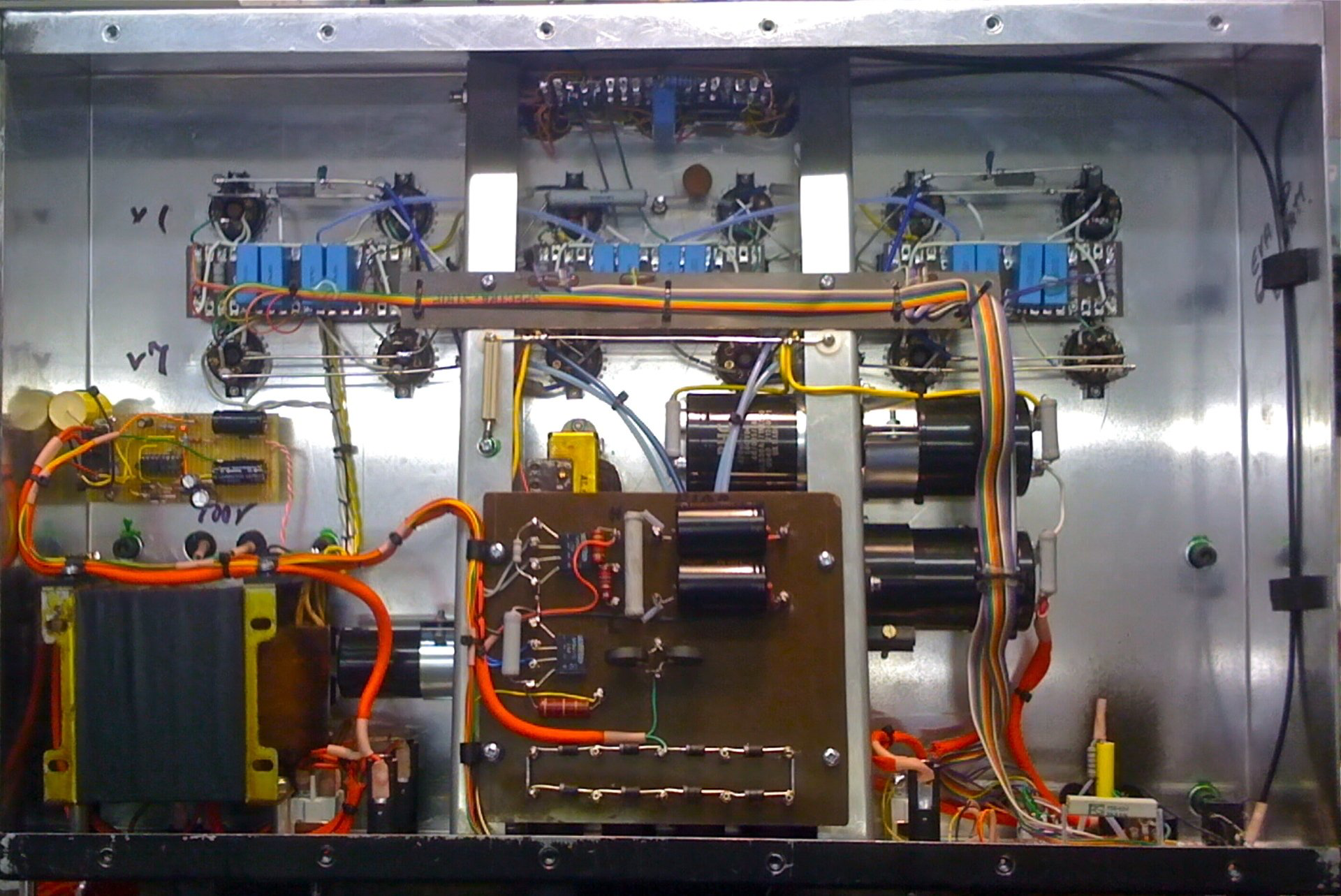

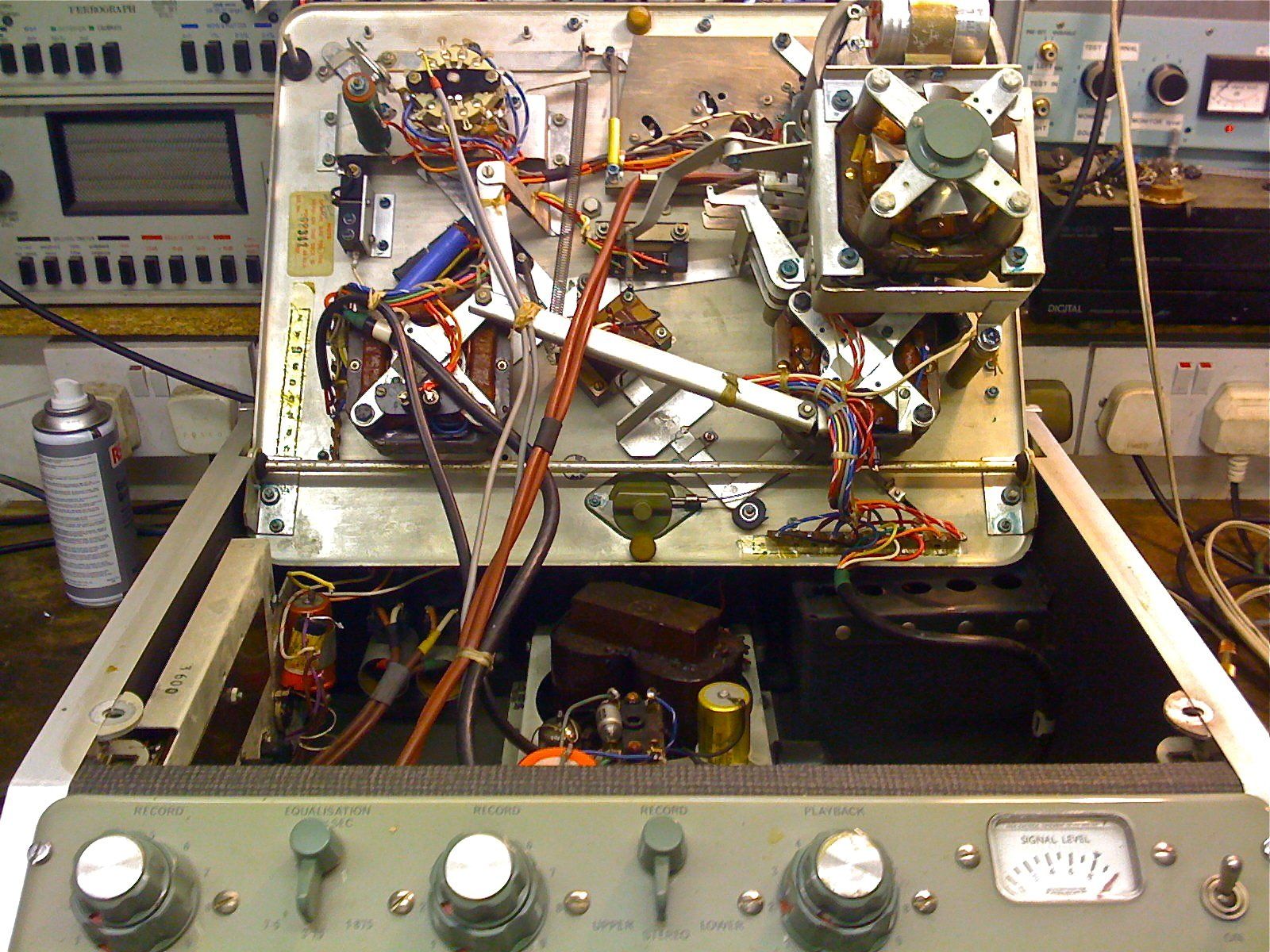

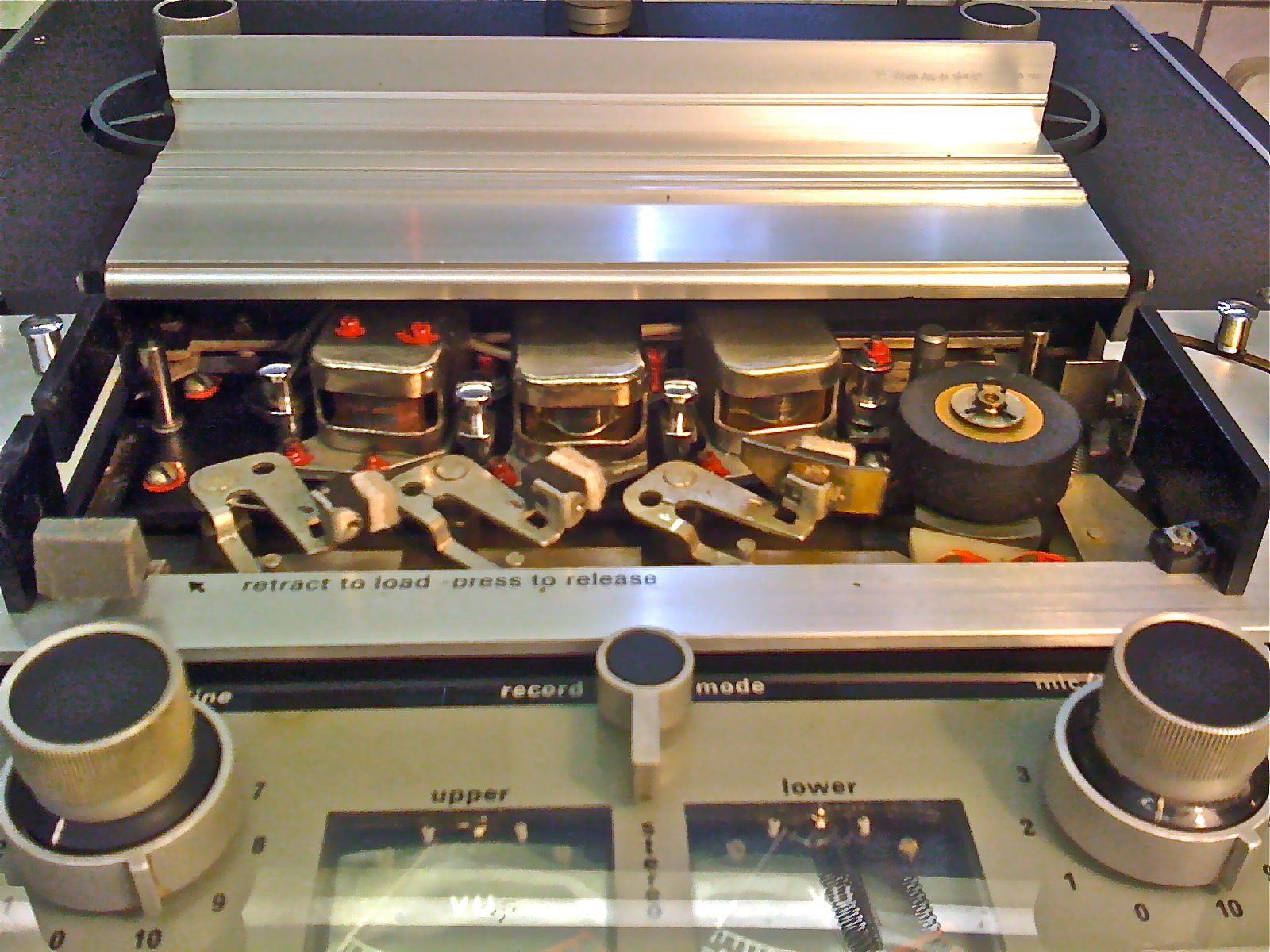

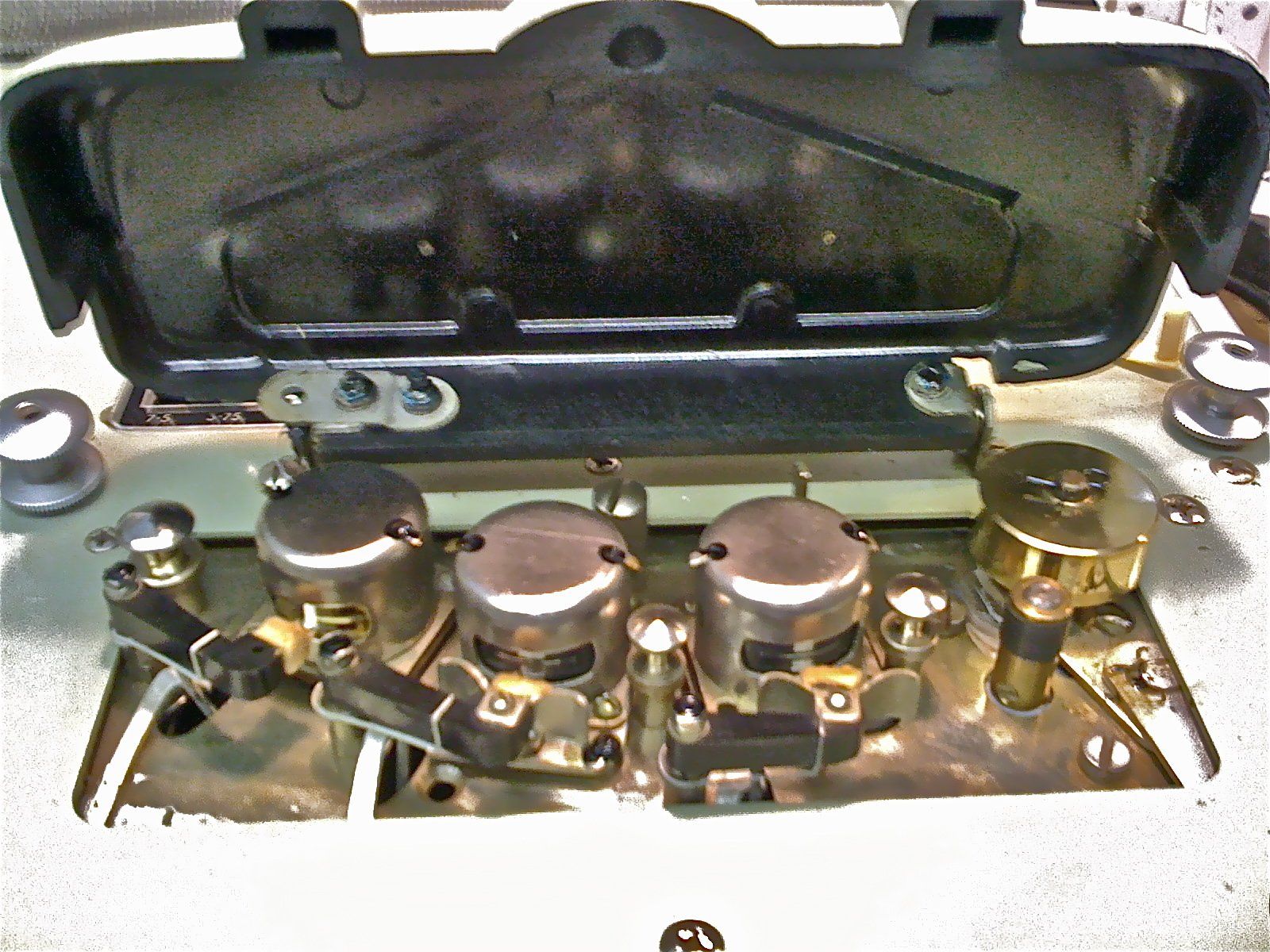

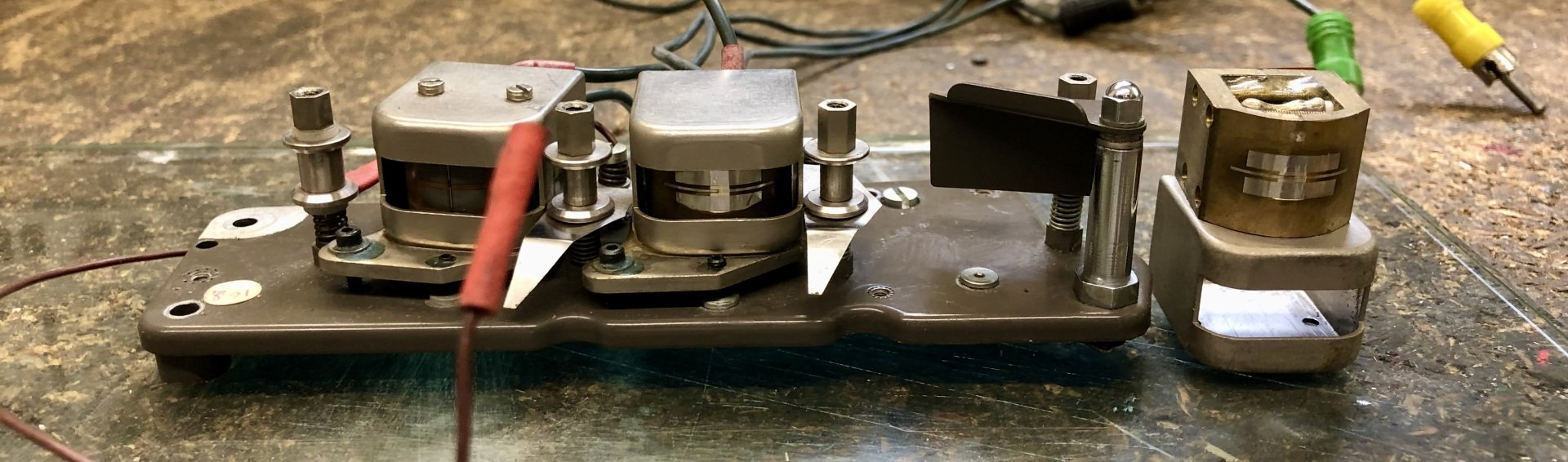

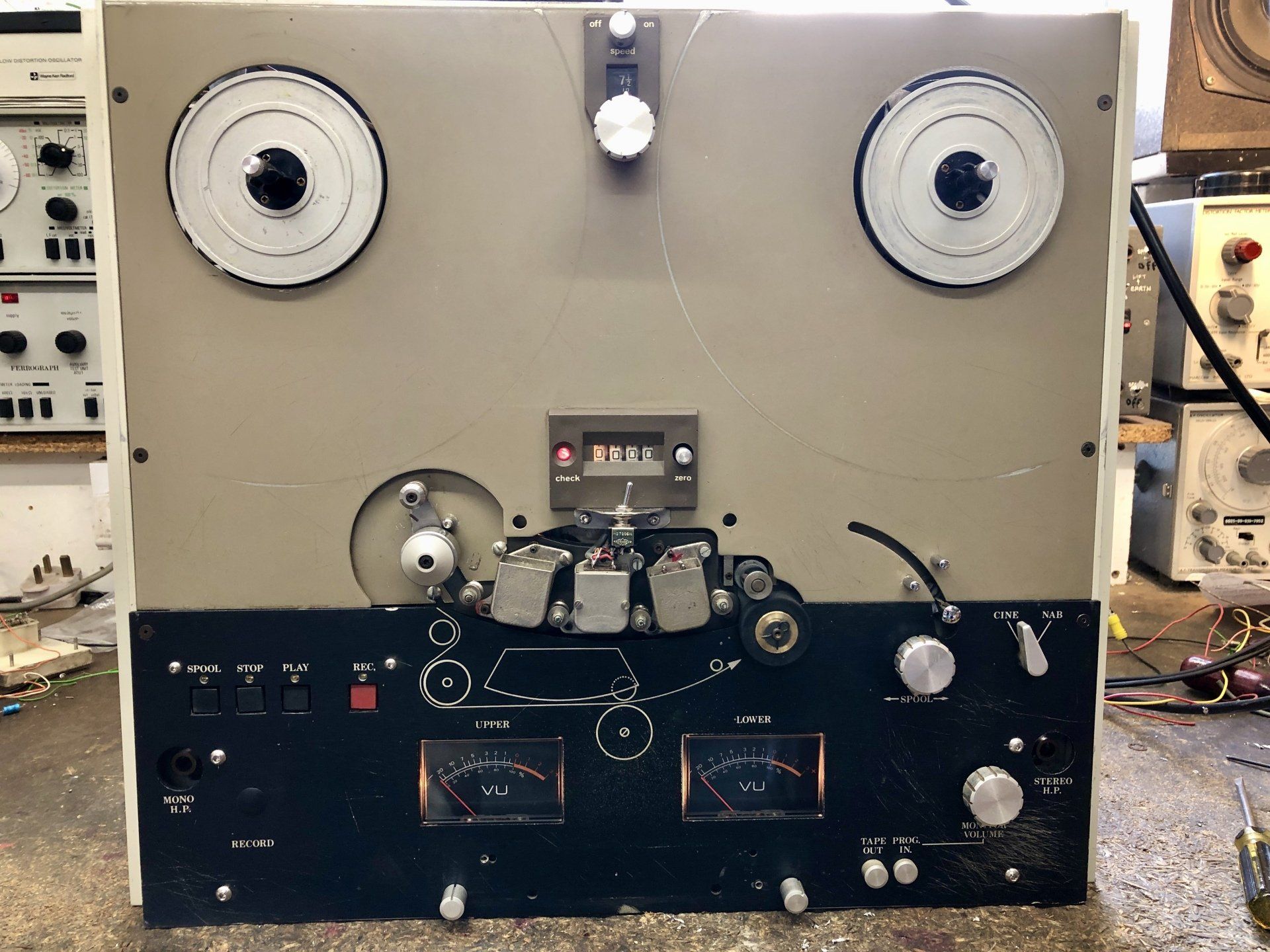

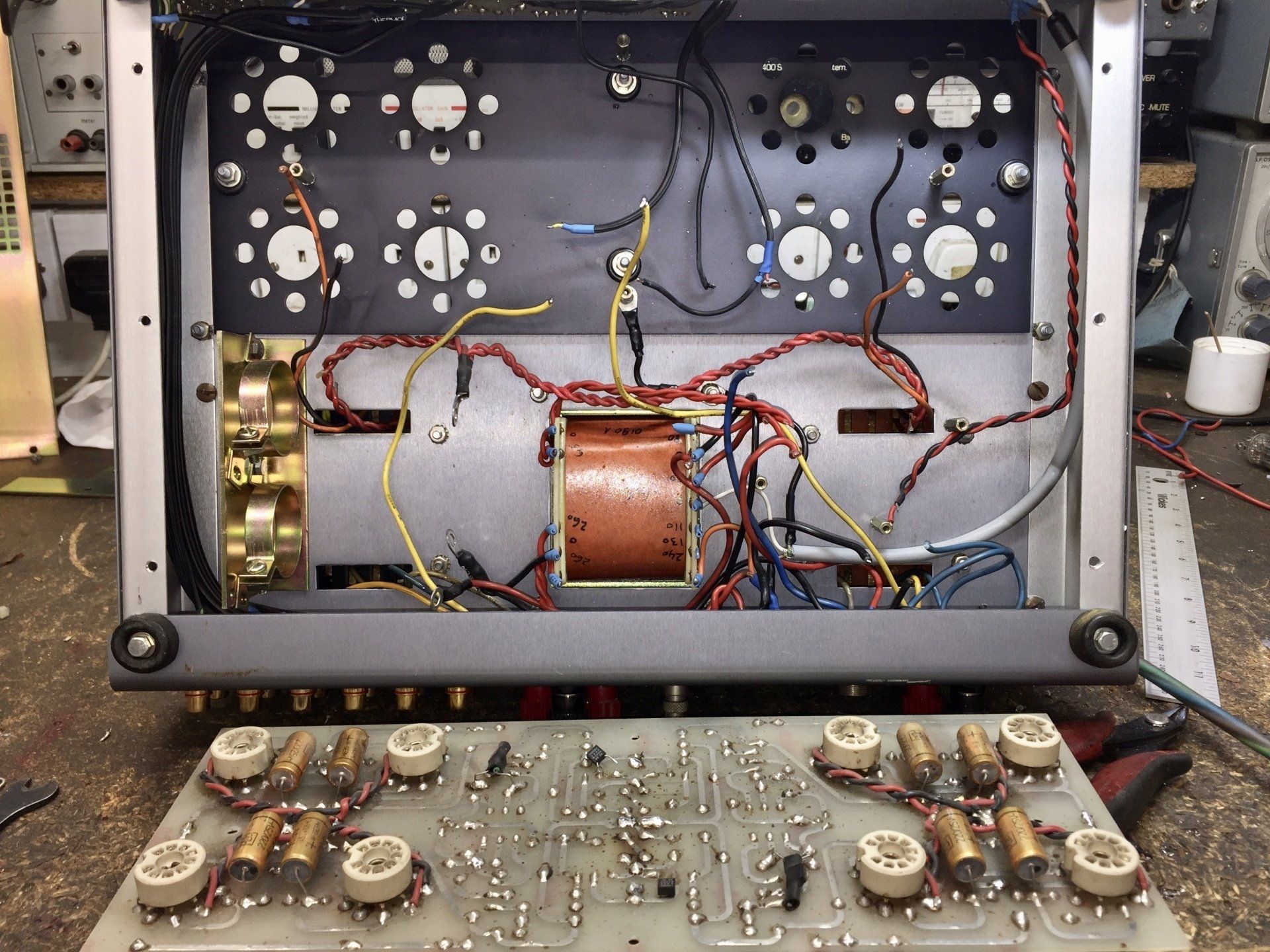

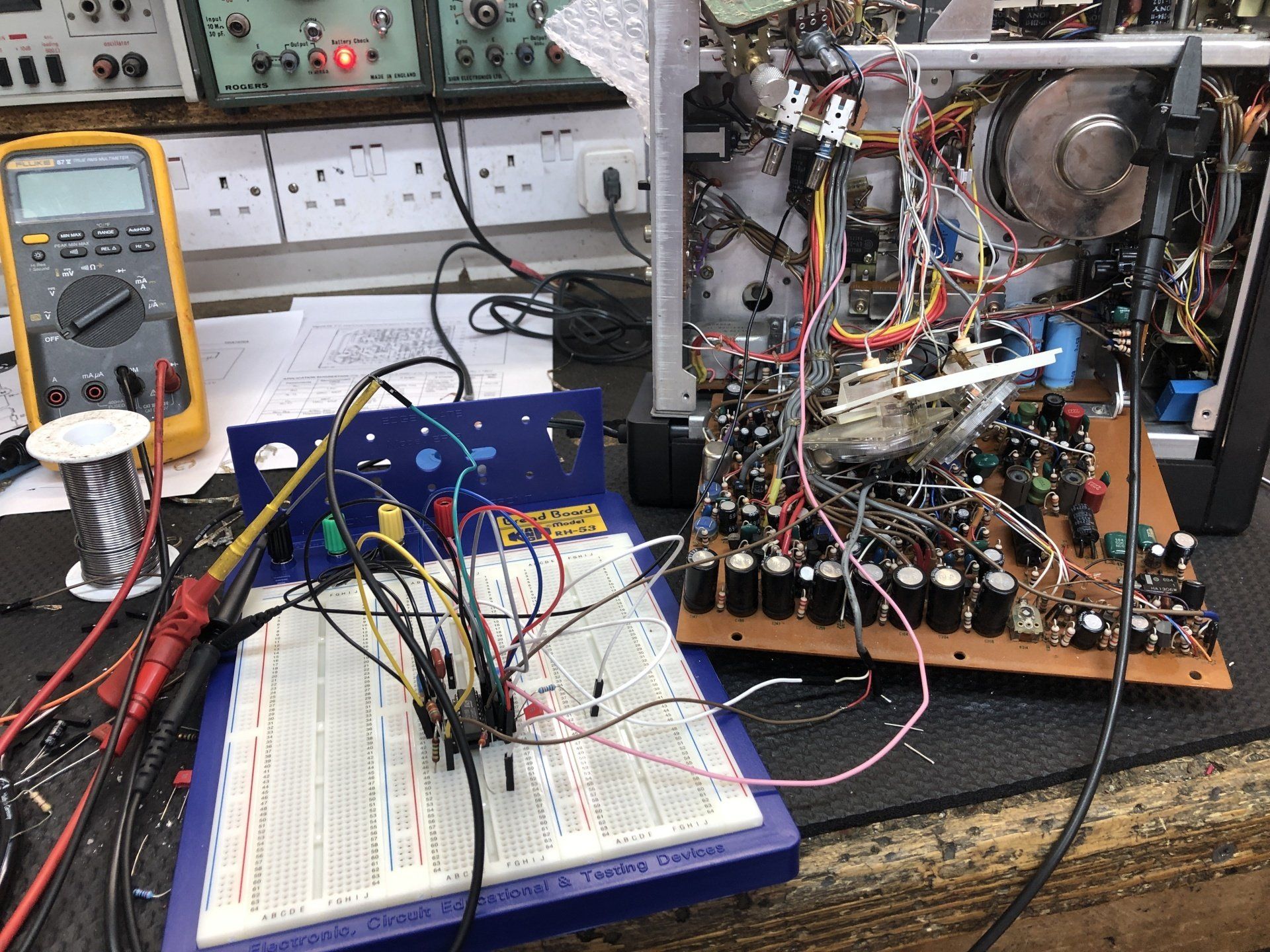

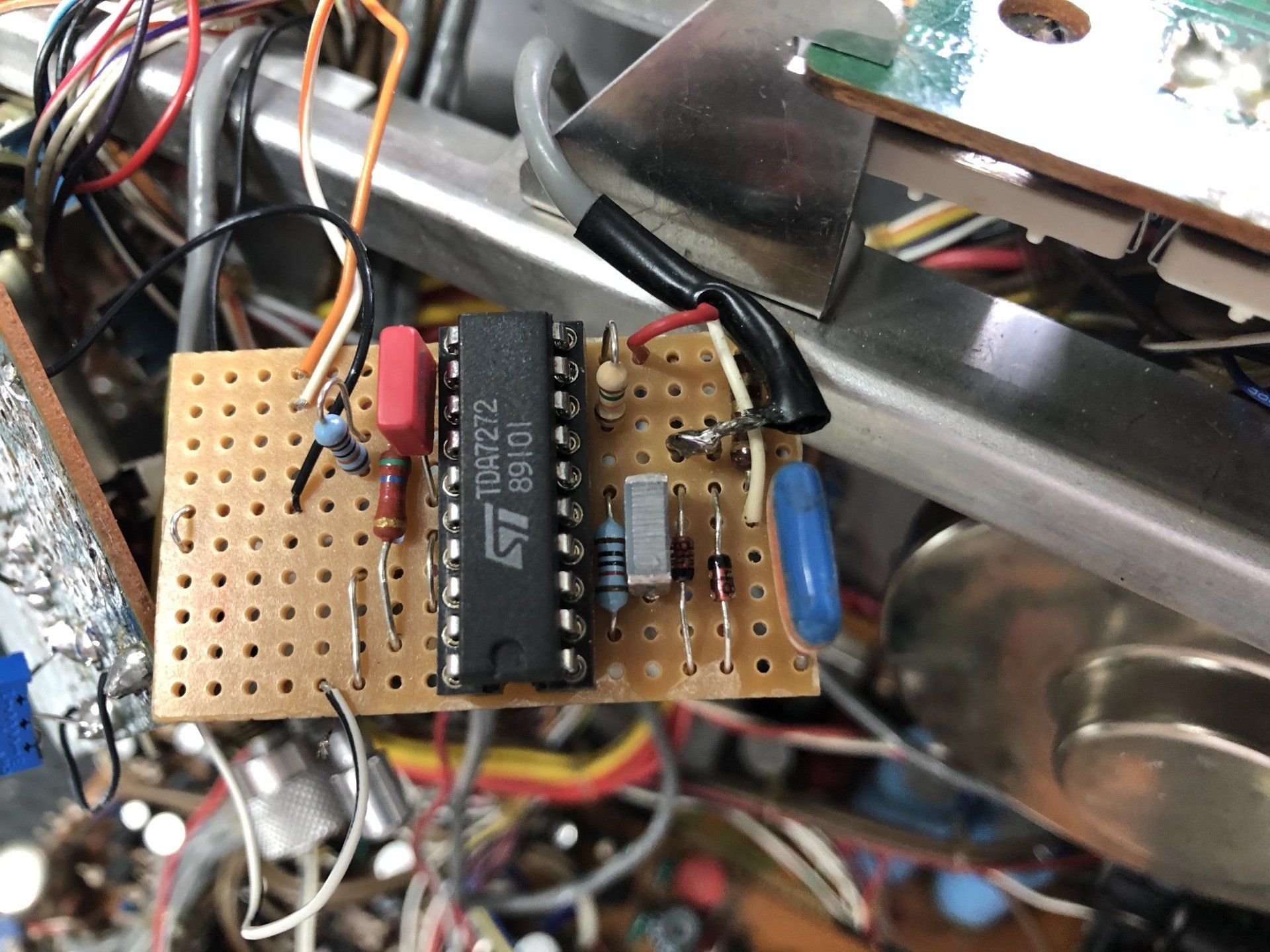

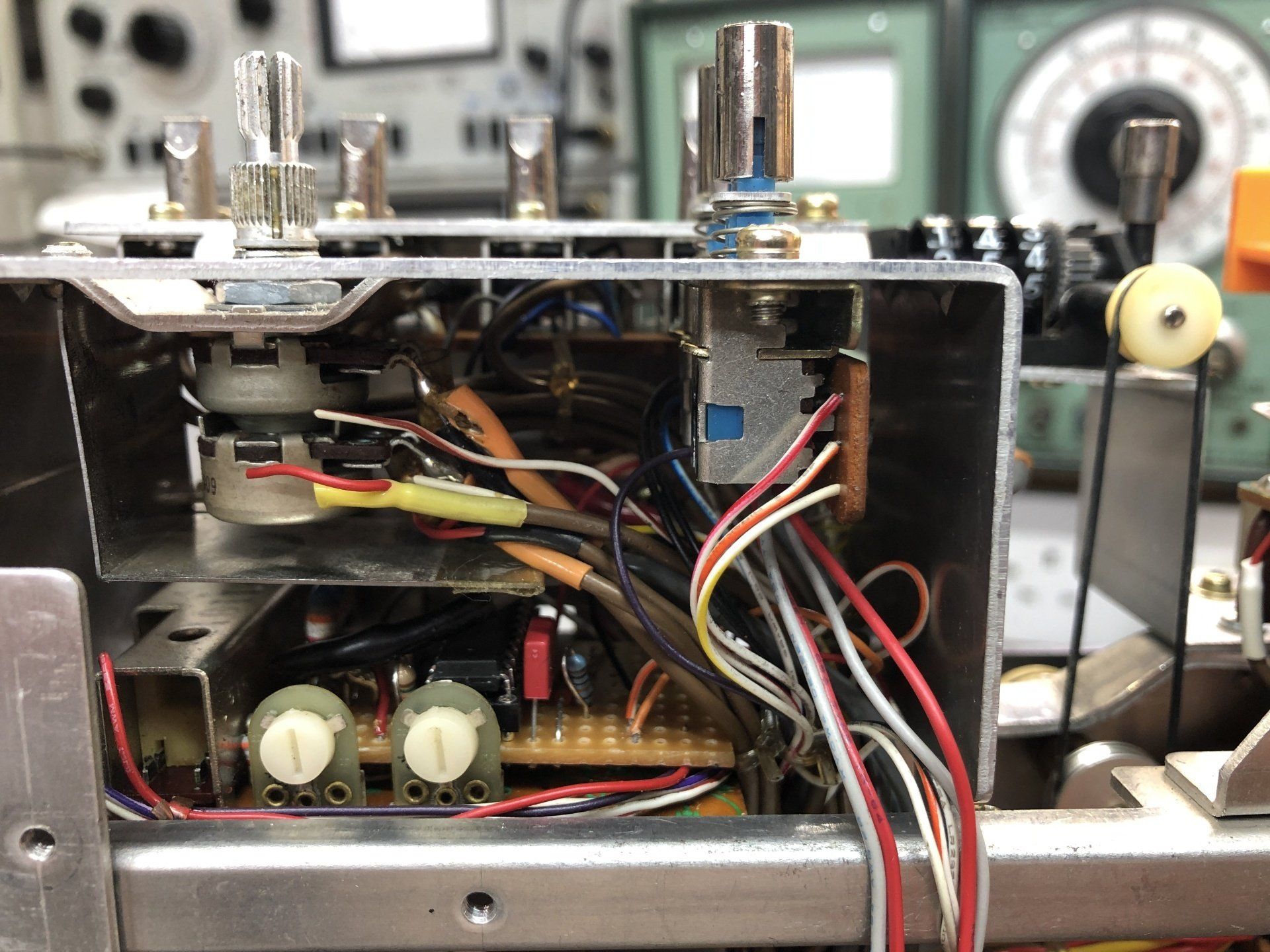

This little Sony TC-510-2 portable reel to reel machine came in with speed problems. Unfortunately the integrated circuit used to control the capstan motor is not available. It was decided that a new circuit be designed using a readily available motor control chip.